For Export Enquiry

Call Us

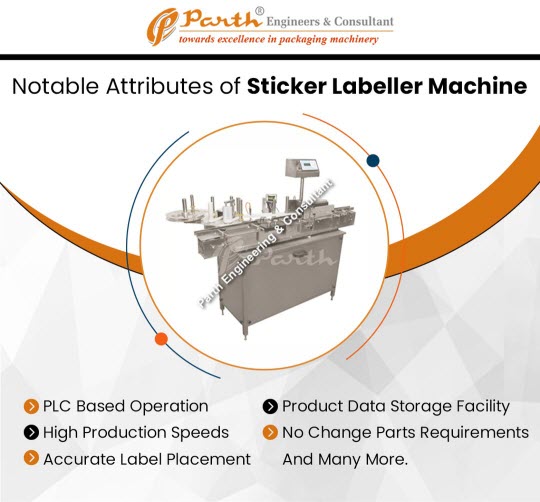

Advanced Sticker Labeling Machines - Increasing your Brand Visibility

In today’s market, standing out is crucial for any brand looking to make a lasting impression. One of the most effective ways to boost brand visibility is through the use of advanced sticker labeling machines. These machines are designed to apply labels quickly and accurately, ensuring that each product is presented in the best possible light. By utilizing these machines, businesses can enhance their product's appearance and make their branding more impactful.

Sticker labeling machines are pivotal in achieving this goal. They streamline the labeling process, allowing for high-speed production and consistent label application. This not only improves operational efficiency but also ensures that every product maintains a uniform look, reinforcing brand identity and helping to capture consumer attention more effectively.

What Are Advanced Sticker Labeling Machines?

Advanced sticker labeling machines are sophisticated devices designed to automate the labeling process with high precision and efficiency. These machines come equipped with features that allow them to handle various labeling tasks seamlessly. They are crucial for businesses that require consistent and high-quality label application on a large scale.

For example, a double side sticker labeling machine is designed to label both sides of a product simultaneously. This feature is particularly beneficial for products that need to display information or branding on multiple surfaces. By using such machines, companies can ensure their products are prominently featured and effectively branded from all angles.

Benefits of Using Advanced Sticker Labeling Machines

Advanced sticker labeling machines offer numerous benefits that can significantly enhance a business's labeling process. They are known for their efficiency, capable of applying labels quickly while maintaining high accuracy. This reduces the time and effort required for manual labeling, leading to greater productivity and cost savings.

A bottle sticker labeling machine is an excellent example of how these machines can cater to specific needs. It ensures that labels are applied neatly and securely on bottles, which is essential for maintaining the product's professional appearance and ensuring it meets industry standards. This precision not only improves product presentation but also helps in brand differentiation.

How Advanced Sticker Labeling Machines Increase Brand Visibility

The impact of advanced sticker labeling machines on brand visibility cannot be overstated. These machines produce high-quality labels that enhance the visual appeal of products. By providing options for customization, businesses can create labels that effectively communicate their brand message and stand out on the shelves.

For instance, using an automatic sticker labeling machine allows for the creation of detailed and eye-catching labels with minimal effort. This automation helps in maintaining label consistency across large production runs, which is crucial for brand recognition and consumer trust.

Key Features to Look For in Advanced Sticker Labeling Machines

When selecting an advanced sticker labeling machine, there are several key features to consider. Speed and production capacity are crucial factors, as they determine how efficiently the machine can handle large volumes of products. Precision is also essential to ensure that labels are applied correctly and do not interfere with the product’s design or functionality.

A double side sticker labelling machine, for example, provides the added benefit of labeling both sides of a product, which can be a valuable feature for products requiring comprehensive branding. Ease of use and maintenance are also important, as they affect the overall efficiency and longevity of the machine.

Applications in Different Industries

Advanced sticker labeling machines are versatile and can be adapted for various industries. In the food and beverage sector, these machines ensure that labels are applied correctly, providing essential information and enhancing product appeal. In pharmaceuticals, precise labeling is critical for compliance and safety, making these machines indispensable.

The use of an ampoule sticker labeling machine in the pharmaceutical industry highlights how these machines cater to specific needs. They ensure that small ampoules are labeled accurately, which is crucial for both regulatory compliance and consumer safety.

Choosing the Right Sticker Labeling Machine for Your Business

Selecting the right sticker labeling machine involves assessing your business's specific needs and comparing different models. Factors such as production volume, label size, and application type will influence your choice. Evaluating these factors helps in selecting a machine that aligns with your operational requirements and budget.

For businesses dealing with small vials, a vial sticker labeling machine might be more suitable, offering the precision needed for smaller items. Conversely, a high-capacity automatic sticker labeling machine might be ideal for larger-scale operations requiring faster production speeds.

Implementing Advanced Sticker Labeling Machines in Your Production Line

Integrating advanced sticker labeling machines into your production line requires careful planning and execution. It involves ensuring that the new machine is compatible with existing systems and training staff to operate it efficiently. Regular maintenance is also necessary to keep the machine in optimal condition and prevent potential downtime.

For instance, an automatic sticker labelling machine can significantly streamline workflows if properly integrated and maintained. This integration helps in optimizing production processes and ensuring that labeling tasks are performed accurately and efficiently.

The Future of Sticker Labeling Technology

The future of sticker labeling technology promises exciting advancements. Emerging trends include more sophisticated automation, enhanced customization options, and improved integration with other production technologies. These innovations are expected to further enhance labeling efficiency and brand visibility.

The development of more advanced automatic sticker labeling machines will likely drive these changes, offering even greater precision and flexibility in labeling applications. Staying informed about these trends can help businesses remain competitive and leverage new opportunities for brand enhancement.

Conclusion

In conclusion, advanced sticker labeling machines play a vital role in enhancing brand visibility and improving labeling efficiency. By choosing the right machine and integrating it effectively into your production line, you can ensure high-quality labeling that contributes to a stronger brand presence and better consumer engagement.

Investing in advanced sticker labeling technology not only improves operational efficiency but also helps in creating a professional and appealing product presentation. As businesses continue to seek ways to stand out, these machines will remain essential tools for achieving branding and marketing goals.

FAQs - Advanced Sticker Labeling Machines

Advanced machines offer enhanced features like higher speed, better accuracy, and versatility compared to standard models. For instance, a double side sticker labeling machine can label both sides of a product simultaneously, which is not possible with standard machines.

By increasing efficiency and reducing the need for manual labor, advanced labeling machines help lower operational costs. Machines like the automatic sticker labeling machine streamline processes and reduce errors, which can lead to cost savings over time.

A bottle sticker labeling machine ensures that labels are applied accurately and consistently on bottles. This enhances the product's appearance and compliance with industry standards, which is crucial for branding and consumer trust.

Yes, an ampoule sticker labeling machine is specifically designed for labeling small ampoules with precision. This ensures that labels are applied correctly, which is essential for regulatory compliance and product safety.

When choosing a sticker labeling machine, consider factors such as production volume, label size, and the type of product. For example, a vial sticker labeling machine is ideal for small vials, while a high-capacity automatic sticker labeling machine suits larger operations.

We provide 24 x 7 Customer

Service & Support

Copyright © 2024, Parth Engineering & Consultant ( India ).

Web Design by Opal Infotech