For Export Enquiry

Call Us

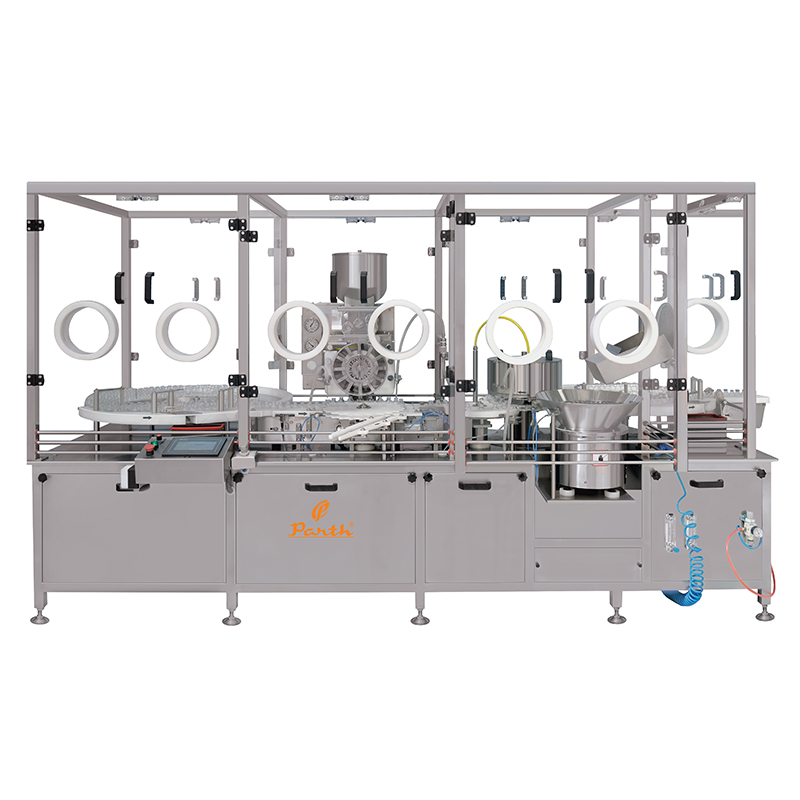

Injectable Powder Filling Machine (Automatic Servo Base Filler)

Automatic Servo Base Injectable Powder Filling Machine

Our Automatic Servo Base Injectable Powder Filling Machine is just the beginning. We offer a diverse array of equipment, including Rotary Vial Washing Machines, Automatic High Speed Linear Bottle Washing to Automatic High Speed Linear Vial Washing, Automatic Servo Base Injectable Powder Filling & Rubber Stoppering Machine, Automatic Vial Cap Sealing Machines, Roller Inspection Conveyors, Inspection Conveyor, Automatic Vial Sticker Labeling Machine, Automatic Vertical Cartoning with Bottle Feeding Provision, and Semi-Automatic Linear Cartoning Machine. Each of these products is engineered to the highest industry standards, offering precision, reliability, and user-friendly operations. With our complete equipment suite, you can optimize your pharmaceutical manufacturing process, reducing downtime, and increasing overall productivity. Trust in Parth Engineers & Consultants for all your pharmaceutical equipment needs and experience the difference in quality and efficiency that our products bring to your operation.

FAQs for Injectable Powder Filling Machine

The Rotary Vial Washing Machines by Parth Engineers & Consultant are designed to facilitate efficient cleaning of vials in pharmaceutical production environments. These machines employ a rotary mechanism that ensures thorough washing by using minimal water and cleaning solutions. Key features include adjustable washing sequences, compatibility with various vial sizes, and compliance with cGMP standards, ensuring they meet stringent hygiene requirements.

This machine streamlines the cleaning process of bottles and vials by using high-speed linear motion. It effectively removes particles and contaminants from the containers through a series of washing and air flushing stages. The equipment is highly automated, ensuring consistent cleanliness with reduced manual intervention, making it ideal for high-throughput pharmaceutical manufacturing.

Parth Engineers & Consultant’s Automatic Servo Base Injectable Powder Filling & Rubber Stoppering Machine is built for precision and speed. It accurately dispenses powder into vials and then securely places a rubber stopper. The servo-driven mechanism enhances the accuracy and repeatability of the fill volumes, which is crucial for maintaining dosage consistency in pharmaceutical products.

The Automatic Vial Cap Sealing Machine is essential for securing the contents of vials in the pharmaceutical industry. It automatically places and seals caps on filled vials at high speeds, ensuring airtight and tamper-evident closures. This machine is vital for maintaining the integrity and sterility of pharmaceutical products throughout their shelf life.

Roller and Inspection Conveyors are used extensively in the packaging lines of pharmaceutical companies to facilitate the smooth transition of products through the inspection phase. These conveyors provide a stable platform for manual or automated inspection of products for defects or contamination. The benefits include enhanced inspection efficiency, reduced labor costs, and improved product quality.

The Automatic Vial Sticker Labeling Machine significantly enhances labeling efficiency by applying labels accurately and rapidly to vials as they pass through the production line. This machine uses sophisticated sensors to ensure precise label placement, which is critical for both aesthetic and regulatory compliance in pharmaceutical packaging.

This innovative machine integrates vertical cartoning with bottle feeding, streamlining the packaging process in pharmaceutical manufacturing. It automatically erects cartons, inserts bottles, and closes them securely, all at high speeds. This integration not only saves time but also reduces the footprint required for separate machines, making it an efficient space-saving solution for manufacturers.

The Semi-Automatic Linear Cartoning Machine provides a balance between automation and manual control, allowing operators to oversee the cartoning process while enjoying the benefits of mechanical precision. This machine is particularly suited for smaller production runs or where product variability requires more frequent adjustments. It offers flexibility, ease of use, and reliability, making it a valuable asset for pharmaceutical packaging tasks.

We provide 24 x 7 Customer

Service & Support

Copyright © 2025, Parth Engineering & Consultant ( India ).

Web Design by Opal Infotech