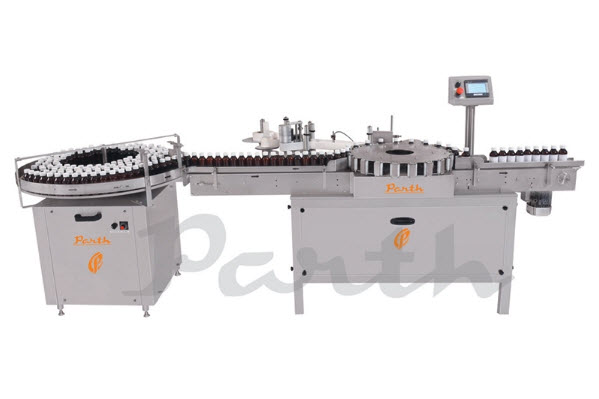

A wrap-around labelling machine has an adjustable angle and is compatible with most bottles and containers. The label countdown feature and the display make it easy to set and position labels. The machine is controlled by a microprocessor and has a product sensing system. It also has an adjustable height, which makes it ideal for a variety of bottle and container sizes. Once installed, a wrap-around labelling machine can easily accommodate bottles and containers.

Future of Wrap-Around Labelling Machine

The market for wrap-around labelling machines is expected to grow over the upcoming years. The growth in the industry is attributed to a shift from manual processes to automated ones. The technology is able to label a wide variety of products, including packages, and can be customized for various applications. In addition, the market is predicted to expand a lot.

Several Advantages of Using Wrap-Around Labelling Machine

The main advantages of a wrap-around labelling machine are the flexibility and reliability of the system. It can divide a bottle smoothly, ensuring a neat label and minimal bubbles. A photoelectric sensor is used to ensure accuracy and high precision. A high-quality wraparound labelling machine can print multiple pieces of information at one time, minimizing labor costs. The wrap-around labelling machine is a cost-effective way to get quality labels for all of your products.

A wrap-around labelling machine is an economical and reliable way to label bottles. Unlike a traditional bottle-stamping machine, it can apply labels on different sizes and types of bottles. This machine has power-assisted web take-up and a high-speed variable-speed conveyor. It can work independently, or as a part of a production line. A wrap-around labelling machine is a flexible and versatile machine, allowing it to work with various types of products.

A wrap-around labelling machine is a versatile machine that can be installed on a conveyor belt. It is easy to use and maintain and is flexible. It can also be used to apply partial wrap labels. It can be used for various purposes, such as in the pharmaceutical industry. A good-quality machine will save you time and money. Its flexibility makes it a smart choice. Once installed, it will ensure that the product gets the maximum exposure.

In Conclusion

A wrap-around labelling machine can also be used for other products. It is an effective and reliable way to label cylindrical bottles. The device is designed to fit most types of cylindrical bottles and can work at higher speeds. A high-speed wrap-around labelling machine is easy to operate and maintain. The speed is dependent on the size of the bottle. A high-speed labelling machine will be capable of working for several hours, depending on the size and orientation of the container.