In the pharmaceutical industry, powder filling machines are indispensable for packaging powdered medications into vials, ampoules, or other containers. These machines ensure precision, efficiency, and compliance with stringent industry standards. When selecting a powder filling machine, manufacturers often face a critical choice: manual powder filling machines or servo-based injectable powder filling machines.

This article provides a comprehensive comparison of these two options, helping you determine which is best for your operational needs.

Understanding Powder Filling Machines

Powder filling machines are used to dispense powdered substances into containers with accuracy. These machines are essential for the pharmaceutical, cosmetic, and chemical industries, where precise dosage and contamination-free processes are critical. Choosing the right type of machine is vital for ensuring efficiency, cost-effectiveness, and product quality.

Manual Powder Filling Machines

Overview

Manual powder filling machines are operated with minimal automation. These machines rely heavily on human intervention for measuring, filling, and sealing processes. They are often used in smaller facilities or for low-volume production.

Advantages of Manual Powder Filling Machines

- Cost-Effective Initial Investment: Manual machines are relatively affordable, making them a viable choice for startups or small-scale manufacturers.

- Simple Operation: With fewer components and no complex programming, these machines are easy to operate and maintain.

- Flexibility: Ideal for small batches or niche products that don’t require high-speed production.

Limitations of Manual Powder Filling Machines

- Low Efficiency: Manual machines are slower and less suited for high-volume production.

- Inconsistent Accuracy: Human intervention increases the likelihood of errors, leading to inconsistent dosing and wastage.

- Higher Labour Costs: Dependence on operators increases Labour expenses and slows production.

- Limited Compliance: These machines may struggle to meet the strict standards of pharmaceutical manufacturing.

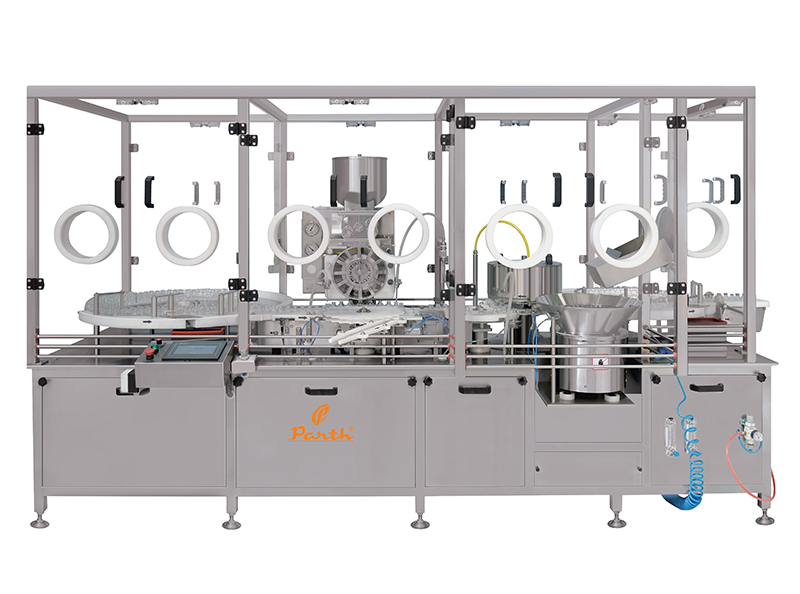

Servo-Based Injectable Powder Filling Machines

Overview

Servo-based injectable powder filling machines are advanced systems that use servo motors for precision control and automation. These machines are highly efficient and ideal for large-scale production in regulated industries like pharmaceuticals.

Advantages of Servo-Based Injectable Powder Filling Machines

- Precision and Accuracy: Servo-based machines excel at dispensing exact amounts of powder, ensuring consistent dosing across all containers.

- High-Speed Operations: These machines can fill thousands of containers per hour, significantly improving productivity.

- Automation: Automated controls reduce reliance on human intervention, minimizing errors and labor costs.

- Compliance with Standards: Servo-based machines meet strict regulatory standards, including GMP and FDA requirements, ensuring safe and hygienic production.

- Versatility: These machines can handle a variety of container sizes, powder consistencies, and fill volumes with ease.

- Error Detection: Advanced sensors identify underfills, overfills, or blockages, ensuring seamless operation.