Automated bottle labeling machines have revolutionized the labeling process, particularly for businesses that produce large quantities of products on a daily basis. Bottle labeling machines are an essential part of a production line. They provide a valuable contribution towards enhancing the visual appeal and augmenting the usability of the product.

The benefits of automated bottle labeling machines include their cost-effectiveness, efficiency, versatility and safety. Automated bottle labeling machines are used in a wide range of industries.

Automated Bottle Labeling Machines are Cost-Effectiveness

If you’re looking for a cost-effective way to label bottles, an automated bottle labeling machine is the ideal solution. This equipment requires minimal space.

In addition to that, you can purchase a variety of models, including those designed specifically for smaller bottles. You can also find more robust models that handle a larger volume of bottles.

Another important factor is how you’ll be using the machine. For example, if you’re planning on labeling multiple products at once, it’s best to choose a machine that supports front/back labels. This will allow you to use a single roll for both the back and front labels.

Automated bottle labeling machines are a cost-effective solution for businesses that produce a high volume of products. While the initial investment in purchasing an automated labeling machine may be higher than the cost of manual labour, the long-term savings can be significant. These machines require minimal maintenance and can run continuously for extended periods, reducing the need for frequent downtime and repair.

Automated labeling mechanisms further aid in mitigating the possibility of exorbitant labeling inaccuracies, which could lead to the dismissal of merchandise, recall, and monetary penalties. This assists in safeguarding the company image and guarantees that products are furnished to customers in accordance with regulatory stipulations.

Automated Bottle Labeling Machine Increases Efficiency

Bottle labeling is an essential part of any packaging process. It helps consumers know the product information such as its brand name, ingredients and other specifications. However, applying labels by hand can be time-consuming and labour-intensive. This is why manufacturers choose to label their products using automated machines.

One of the most significant benefits of automated bottle labeling machines is the increased efficiency they offer. Automated bottle labeling machines are designed to label bottles at a much faster rate than can be achieved manually. Manufacturers possess the capability to fabricate a larger quantity of merchandise in a significantly reduced duration, a pivotal element for enterprises that confront elevated demands for product manufacture.

Automated bottle labeling machines also reduce the need for manual labor, freeing up employees to concentrate on other tasks within the production line. Not merely does this augment comprehensive efficiency, but it also assists in curbing the possibility of worker exhaustion and harm.

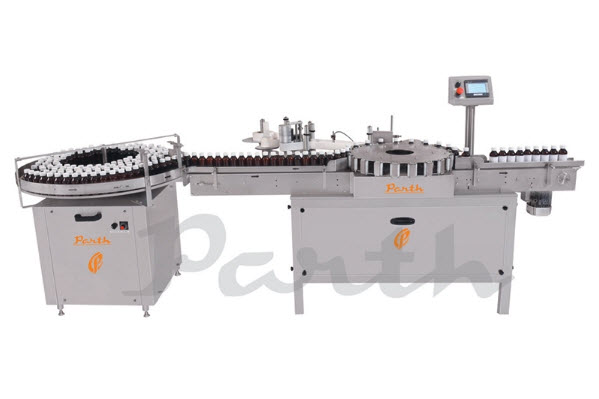

A fully automatic bottle labeling machine is an ideal solution for organizations looking to increase their efficiency and production. It can handle a higher number of containers per minute, thereby reducing the labour costs associated with each unit of product.

Automated Bottle Labeling Machine is Versatile

The versatility of automated bottle labeling machines is a key advantage that sets them apart from manual equipment. These units can label a wide range of bottle sizes, including those with complex designs.

These machines also offer the ability to direct labels through a touchscreen, thereby eliminating human error. This constitutes a monumental advantage since it can aid in warranting that your labeling is precise and standardized.

Automated bottle labeling machines are available in a variety of models and designs, making them versatile for use in different industries and production environments. These machines can be customized to meet specific labeling requirements, including the use of different label materials and printing technologies. This makes automated bottle labeling machines ideal for use in industries such as food and beverage, pharmaceuticals, cosmetics, and household products. Automated labeling machines can also be integrated into existing production lines, providing a seamless labeling solution that does not disrupt the overall production process.

Automated Bottle Labeling Machine Improves Safety

Manual bottle labeling can be a perilous task, particularly if employees are required to work with sharp tools or in awkward positions. Automated bottle labeling machines eliminate the need for manual labor, reducing the risk of employee injury and fatigue. This helps to create a safer working environment and improves overall workplace morale.

Automated labeling machines are also designed with safety features that help to prevent accidents and injuries. These features include sensors that detect the presence of foreign objects, emergency stop buttons, and automatic shutdown mechanisms.

Automated Bottle Labeling Machine Improves Accuracy

The accuracy of labeling is of paramount importance in ensuring that products are appropriately identified and adhere to regulatory requirements. Automated bottle labeling machines offer improved accuracy compared to manual labeling, as they are equipped with sensors that can detect the exact position of the label on the bottle. This ensures that each bottle is labeled precisely and consistently, reducing the risk of labeling errors that can result in costly rejections or recalls.