For Export Enquiry

Call Us

Why Bottle Filling Machines are Essential for Modern Manufacturing

The Evolution of Manufacturing

Manufacturing has evolved significantly from its early days of handcrafting to the highly automated processes we see today. This evolution has been driven by the need for efficiency, precision, and mass production. Early manufacturing relied heavily on manual labour, which was time-consuming and prone to errors. As industries expanded, the demand for faster production methods led to the development of machinery and assembly lines, revolutionising the way products were made.

In the modern era, technological advancements such as robotics, artificial intelligence, and IoT have further transformed manufacturing. These innovations have enabled higher production rates, better quality control, and reduced costs. The integration of automated systems has also allowed for more complex and precise manufacturing processes, meeting the growing demands of various industries. This continuous evolution underscores the importance of adopting new technologies, such as bottle filling machines, to stay competitive in today's market.

Introduction to Bottle Filling Machines

Bottle filling machines are essential devices used in various industries to automate the process of filling containers with liquids, powders, or granules. These machines ensure that each bottle is filled accurately and efficiently, maintaining consistency and reducing waste. They come in various types and configurations, each designed to handle specific types of products and production requirements.

The primary function of bottle filling machines is to streamline the production process, increasing speed and reducing manual labour. They are widely used in the beverage, pharmaceutical, cosmetic, and chemical industries, where precise filling is crucial. By automating this process, manufacturers can achieve higher productivity, improve product quality, and ensure compliance with industry standards. The versatility and efficiency of these machines make them indispensable in modern manufacturing.

Types of Bottle Filling Machines

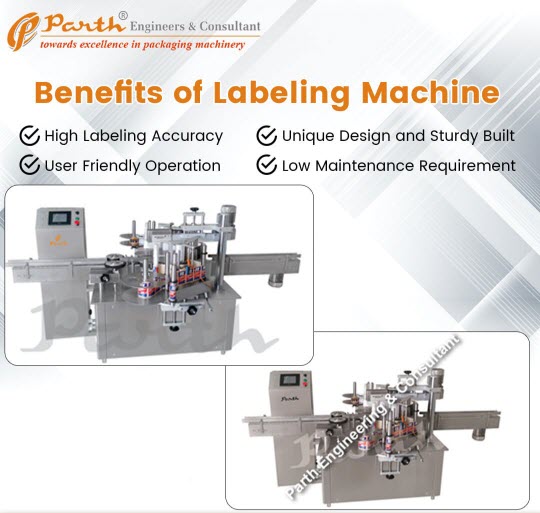

Automatic Bottle Labelling Machine

Automatic bottle labelling machines are designed to apply labels to bottles with minimal human intervention. These machines are equipped with advanced sensors and control systems that ensure each label is applied accurately and consistently. They can handle a wide range of bottle shapes and sizes, making them suitable for various industries, including food and beverage, pharmaceuticals, and cosmetics.

One of the key benefits of automatic bottle labelling machines is their ability to operate at high speeds, significantly increasing production rates. They also reduce the risk of human error, ensuring that each product is labelled correctly. This not only enhances the appearance of the products but also ensures compliance with labelling regulations. The efficiency and reliability of these machines make them a valuable addition to any manufacturing line.

Round Bottle Labeling Machine

Round bottle labeling machines are specifically designed to apply labels to cylindrical containers. These machines use rollers or belts to rotate the bottles, allowing the labels to be applied smoothly and evenly. They are commonly used in the beverage industry for labelling bottles of water, juice, and other drinks.

These machines are highly versatile and can accommodate various label sizes and materials. They are also equipped with features such as automatic label detection and alignment, ensuring precise placement of each label. The ability to handle different types of labels and bottles makes round bottle labeling machines an essential tool for manufacturers looking to improve their labelling processes.

Flat Bottle Labeling Machine

Flat bottle labeling machines are designed for containers with flat surfaces, such as rectangular or square bottles. These machines use pressure-sensitive or adhesive labels that are applied directly to the flat surfaces, ensuring a clean and professional finish. They are widely used in the pharmaceutical, cosmetic, and household product industries.

These machines offer several advantages, including the ability to label both the front and back of the bottles simultaneously. This dual-labelling capability enhances the product's appearance and provides more space for branding and information. Flat bottle labeling machines are also known for their precision and speed, making them ideal for high-volume production environments.

Square Bottle Labeling Machine

Square bottle labeling machines are tailored for labelling containers with square or rectangular shapes. These machines ensure that labels are applied accurately to each side of the bottle, maintaining a neat and professional appearance. They are commonly used in the food and beverage, pharmaceutical, and chemical industries.

These machines are equipped with advanced features such as automatic bottle positioning and label application. This ensures that each label is placed correctly, regardless of the bottle's orientation. The ability to handle different label sizes and materials makes square bottle labeling machines a versatile and efficient solution for manufacturers.

Specialized Labeling Machines

Self Adhesive Bottle Sticker Labelling Machine

Self-adhesive bottle sticker labelling machines apply labels that have an adhesive backing, which sticks directly to the bottle's surface. These machines are highly efficient and capable of applying labels at high speeds, making them ideal for large-scale production. They are commonly used in the food and beverage, pharmaceutical, and cosmetic industries.

One of the main benefits of self-adhesive labelling machines is their ability to apply labels precisely and consistently. This reduces the risk of misalignment and ensures a professional appearance for each product. Additionally, these machines are versatile and can handle various types of labels, including those with complex shapes and designs.

Bottle Sticker Labeling Machine

Bottle sticker labeling machines are designed to apply adhesive labels to a wide range of bottle shapes and sizes. These machines use sensors and control systems to ensure that each label is applied accurately and efficiently. They are widely used in the beverage, pharmaceutical, and personal care industries.

These machines offer several advantages, including the ability to handle high production volumes and the flexibility to accommodate different types of labels. The precision and consistency provided by bottle sticker labelling machines help manufacturers maintain a high standard of quality for their products. This makes them an essential tool for any production line that requires labelling.

Benefits of Bottle Labelling Machines

Efficiency and Speed

Bottle labelling machines significantly enhance the efficiency and speed of the labelling process. These machines are designed to handle large volumes of bottles, applying labels quickly and accurately. This not only increases production rates but also reduces the time and labour required for manual labelling.

The use of bottle labelling machines also ensures consistency and precision in the application of labels. This is crucial for maintaining the quality and appearance of the products. By automating the labelling process, manufacturers can achieve higher productivity and meet the demands of a fast-paced market.

Consistency and Accuracy

One of the key benefits of bottle labelling machines is their ability to provide consistent and accurate labelling. These machines use advanced sensors and control systems to ensure that each label is applied precisely in the same position on every bottle. This eliminates the variability that can occur with manual labelling.

Consistency in labelling is important for maintaining a professional appearance and ensuring that all regulatory requirements are met. Accurate labelling also helps in reducing waste, as there are fewer mislabelled bottles that need to be discarded. This improves the overall efficiency and cost-effectiveness of the production process.

Cost-Effectiveness

Investing in bottle labelling machines can lead to significant cost savings in the long run. These machines reduce the need for manual labour, which can be expensive and prone to errors. By automating the labelling process, manufacturers can lower their operational costs and increase their profit margins.

In addition to labour savings, bottle labelling machines also reduce material waste by ensuring that each label is applied correctly. This minimises the number of rejected products and improves overall efficiency. The initial investment in these machines is quickly offset by the long-term savings and increased production capacity.

Diverse Applications

Pharmaceutical Bottle Labeler

Pharmaceutical bottle labellers are essential for ensuring that medication bottles are labelled accurately and in compliance with strict industry regulations. These machines are designed to handle the unique requirements of pharmaceutical products, such as small bottles and precise labelling.

The importance of accurate labelling in the pharmaceutical industry cannot be overstated. Incorrect labels can lead to serious health risks and legal consequences. Pharmaceutical bottle labellers provide the precision and reliability needed to ensure that each bottle is correctly labelled, enhancing patient safety and regulatory compliance.

Water Bottle Labelling Machine

Water bottle labelling machines are specifically designed to handle the high-speed production needs of the bottled water industry. These machines apply labels quickly and accurately, ensuring that each bottle meets the industry's quality standards. They are essential for maintaining the efficiency and consistency of large-scale production lines.

These machines are equipped with features such as automatic bottle detection and alignment, which ensure that each label is applied in the correct position. This enhances the visual appeal of the bottles and helps brands maintain a professional image. The use of water bottle labelling machines also reduces the risk of human error, improving overall production efficiency.

Square Bottle Labelling Machine

Square bottle labelling machines are designed to handle the specific requirements of labelling square or rectangular bottles. These machines ensure that each label is applied accurately to all sides of the bottle, providing a neat and professional appearance. They are widely used in the food and beverage, pharmaceutical, and chemical industries.

The ability to label square bottles precisely is important for maintaining product quality and consistency. These machines use advanced positioning systems to ensure that each label is placed correctly, regardless of the bottle's orientation. This reduces the risk of mislabelled products and enhances the overall efficiency of the production process.

Integration in Manufacturing Processes

Automation and Control Systems

The integration of automation and control systems in bottle labelling machines enhances their efficiency and reliability. These systems allow for seamless operation, reducing the need for manual intervention and increasing production speed. They also ensure that each label is applied with precision, maintaining a high standard of quality.

Automation systems can be customised to meet the specific needs of different production lines. This flexibility allows manufacturers to optimise their labelling processes and improve overall efficiency. The use of advanced control systems also enables real-time monitoring and adjustment, ensuring that any issues are quickly identified and resolved.

Maintenance and Durability

Regular maintenance is crucial for ensuring the durability and longevity of bottle labelling machines. These machines are designed to withstand the demands of high-speed production, but regular upkeep is necessary to keep them running smoothly. This includes routine inspections, cleaning, and replacement of worn parts.

Proper maintenance not only extends the life of the machines but also ensures that they operate at peak efficiency. This reduces the risk of downtime and costly repairs, improving overall production reliability. Investing in high-quality maintenance practices is essential for maximising the return on investment in bottle labelling machines.

Future Trends and Innovations

Technological Advancements

The future of bottle labelling machines is shaped by ongoing technological advancements. Innovations such as AI, machine learning, and IoT are being integrated into these machines, enhancing their capabilities and efficiency. These technologies enable more precise control and monitoring, improving the overall performance of the machines.

Emerging technologies also allow for greater customisation and flexibility in labelling. Manufacturers can easily adapt their labelling processes to meet changing market demands and regulatory requirements. The integration of these advanced technologies is driving the evolution of bottle labelling machines, making them more efficient and versatile.

Sustainability in Labelling

Sustainability is becoming an increasingly important consideration in the manufacturing industry. Bottle labelling machines are being designed with eco-friendly features, such as reduced energy consumption and the use of recyclable materials. This helps manufacturers minimise their environmental impact and meet sustainability goals.

The shift towards sustainable labelling practices is also driven by consumer demand for environmentally friendly products. By investing in sustainable labelling solutions, manufacturers can enhance their brand image and appeal to eco-conscious consumers. The move towards sustainability is a key trend shaping the future of bottle labelling machines.

Customisation and Flexibility

Customisation and flexibility are becoming essential features of modern bottle labelling machines. These machines are designed to handle a wide range of bottle shapes and sizes, as well as various types of labels. This versatility allows manufacturers to meet diverse production needs and adapt to changing market trends.

The ability to customise labelling processes enhances the efficiency and effectiveness of production lines. Manufacturers can easily switch between different products and labels, reducing downtime and increasing productivity. The flexibility offered by modern bottle labelling machines is crucial for staying competitive in today's fast-paced market.

Conclusion

Bottle filling machines play a pivotal role in modern manufacturing by enhancing efficiency, consistency, and cost-effectiveness. From automatic and round bottle labelling machines to flat and square bottle labelling machines, each type offers unique benefits tailored to specific industry needs. These machines not only streamline production processes but also ensure precise and accurate labelling, which is crucial for maintaining product quality and meeting regulatory standards. The evolution of bottle labelling technology, including the introduction of self-adhesive and pharmaceutical bottle labellers, highlights the industry's commitment to innovation and sustainability.

FAQs - Bottle Filling Machines

When selecting a bottle labeling machine, it is important to consider key features such as speed, accuracy, and versatility. High-speed machines can handle large production volumes, while accurate labeling ensures consistency and compliance with regulations. Versatility allows the machine to accommodate different bottle shapes and sizes, enhancing its utility across various applications.

Additionally, advanced control systems and automation features are crucial for ensuring efficient operation and reducing the need for manual intervention. Other important considerations include ease of maintenance, durability, and the ability to integrate with existing production lines. Evaluating these features helps manufacturers choose the right machine for their specific needs.

Round bottle labeling machines are specifically designed to apply labels to cylindrical containers, using rollers or belts to rotate the bottles for smooth and even application. They are ideal for industries such as beverages, where round bottles are common. In contrast, flat bottle labeling machines are designed for containers with flat surfaces, using pressure-sensitive or adhesive labels to ensure a clean finish.

The main difference lies in the bottle handling mechanism and the type of labels used. Round bottle labeling machines focus on consistent rotation for accurate label placement, while flat bottle labeling machines ensure even pressure distribution on flat surfaces. Both types offer precision and efficiency but cater to different bottle shapes and industry requirements.

Automatic bottle labelling machines are beneficial across various industries, particularly those with high production volumes and stringent labelling requirements. The food and beverage industry relies on these machines for quick and accurate labelling of products such as water, juices, and sauces. The pharmaceutical industry also benefits from precise labelling to ensure compliance with safety regulations.

Other industries, such as cosmetics, chemicals, and household products, use automatic bottle labelling machines to maintain consistent product presentation and meet consumer expectations. The versatility and efficiency of these machines make them indispensable for any industry that requires high-quality and reliable labelling.

Regular maintenance is essential for ensuring the optimal performance and longevity of bottle labelling machines. This includes routine inspections to identify and address wear and tear, as well as cleaning to prevent the buildup of adhesive and dust. Lubrication of moving parts and calibration of sensors and control systems are also important maintenance tasks.

Replacing worn or damaged components promptly helps prevent breakdowns and ensures consistent operation. Manufacturers should follow the maintenance guidelines provided by the machine's manufacturer and consider implementing a preventative maintenance schedule to minimise downtime and maximise productivity.

Self adhesive bottle sticker labelling machines enhance production efficiency by automating the label application process, reducing the need for manual labour and minimising human error. These machines apply labels quickly and accurately, ensuring consistent placement and a professional appearance for each product.

The use of self adhesive labels eliminates the need for additional adhesive application steps, streamlining the process and reducing production time. Additionally, the precision of these machines reduces waste by minimising the number of mislabelled products. The overall efficiency improvements contribute to higher production rates and cost savings for manufacturers.

We provide 24 x 7 Customer

Service & Support

Copyright © 2025, Parth Engineering & Consultant ( India ).

Web Design by Opal Infotech