For Export Enquiry

Call Us

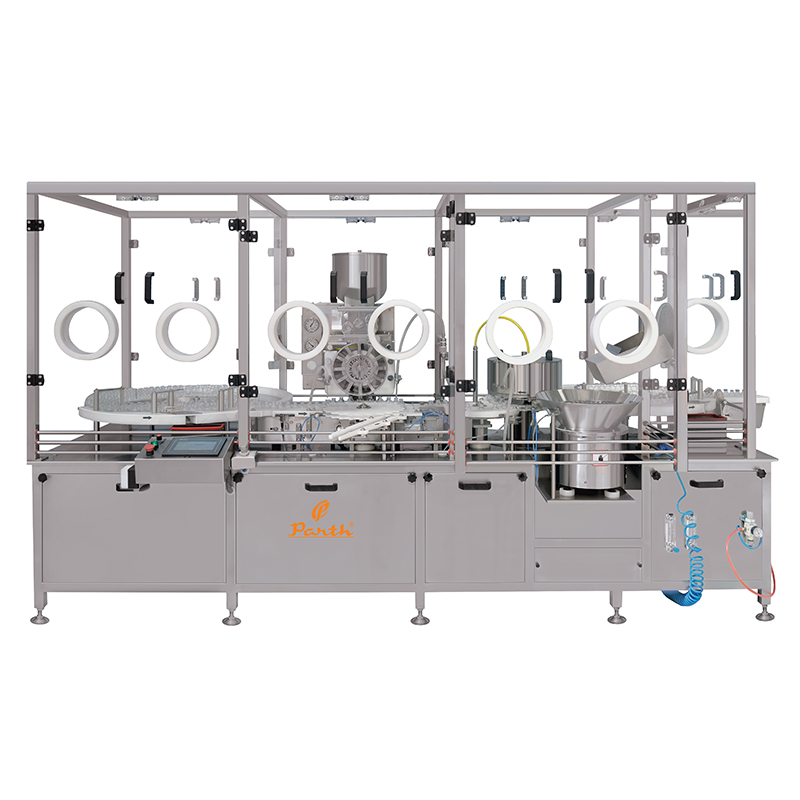

Injectable Powder Filling Machine & Rubber Stoppering – 120/240

Automatic Inject able Powder Filling& Rubber Stoppering Machine is compact machine used for filling of the Inject able Powder in vials and bunging of filled vials is most ideal for wide application in PHARMA INDUSTRIES. It is built on strong and robust powder coated M.S. Angle frame Pipe Structure encompassed with S.S.304 hair lined pre-finished coverings.

Operation of Automatic Servo Base Injectable Powder Filling Machine & Rubber Stoppering

In case of servo base dry powder vial filling machine the powder wheel is indexing manner is to be controlled by servo with help of PLC and HMI , vial holding starplate also controlled by servo due to servo it’s easy to set multiple doze by touch screen without any limit

Automatic Servo Base Injectable Powder Filling & Rubber Stoppering Machine Filling Process

The basic concept of filling is to fill desire volume of powder into the vial. The function of the machine, sterile vial will come in turn table from the sterilize tunnel and move to the conveyor. The conveyor supply vial to starplate in indexing manner with help of servo during the movement starplate pick up two vial same time and pass two vial to filling station. Once vial reach to filling station meantime preloaded powder reach in secondary hopper from primary hopper where the agitator will supply the powder to the port of the powder wheel with help of vacuum. Once port to be filled in the powder wheel then after it will rotate by servo mechanism during the time extra powder on wheel will be remove the powder by doctor blade. Once cavity port reach to above vial, the time sensor will give command and vacuum will cut off and air is to be flush powder in the vial. The machine having facility for the multiple dose if we wish to fill multiple dose. Complete the above operation star wheel move the vial for the next station where empty vial to be filled as same manner. Here one vial to be filled in first station and empty vial fill in second station.

Automatic Servo Base Injectable Powder Filling & Rubber Stoppering Machine Sampling unit- (Optional)

After filling there is a sampling station where starplate hold the Vial and move on the trey as per required quantity whenever required.

Automatic Servo Base Injectable Powder Filling & Rubber Stoppering Machine Rubber Stoppering Unit

The rubber stoppering unit is mounted on the top plate of the machine. The basic principle of the stoppering unit is working on vacuum base pick and place system. The rubber stopper is fed by the vibratory bowl which feed the stopper in correct position into the chute. The chute delivers the stoppers on the stopper holding plate. The stopper holding plate held the stoppers by vacuum and run along the vial. During one position the vial is lifted up by cam. During this up position, the stopper is pressed into the neck of the vial. After this operation, the vacuum gets released. This whole system is suitable for half stoppering also.

Technical Specification of Automatic Servo Base Injectable Powder Filling & Rubber Stoppering Machine

| Model | PIPF-120 | PIPF-240 | ||

|---|---|---|---|---|

| Output/Hour* | Up to 7200* | Up to 14400* | ||

| Fill Volume | 30 mg to 1250 mg Single Dose 1.5 gm. to 5 gm. Multi Dose (With Change Part) |

|||

| Direction of Movement** | Left to Right | |||

| Power Consumption** | Main Motor | 3.5 HP / 415 Volts / 50 Hz. | ||

| Conveyor | Synchronized | |||

| Vacuum pump | 2 HP | |||

| Height of Conveyor** | 850 mm to 900 mm Adjustable. | |||

| Dimensions** | 4000 mm (L) X 1450mm (W) X 2800mm (H) | |||

| Case Dimensions | 4200mm (L) X 1650mm (W) X 3000mm (H) | |||

| Net Weight | 2000 Kgs. Approx. | |||

| Gross Weight | 3000 Kgs. Approx. | |||

Automatic Servo Base Injectable Powder Filling & Rubber Stoppering Machine Input Specifications:

| Container Neck Diameter** | Minimum 20 to 32mm*** | |

|---|---|---|

| Container Size** | Round Shape | Ø 20 mm to Ø 60 mm Respectively height 58 mm to 120 mm (Height option for other Vial height available) |

| Rubber Stopper | 20-32 mm diameter. | |

Note: * Depends on Container size, Neck diameter of container etc.

** We can supply as per customer requirements.

*** With help of change parts.

** We can supply as per customer requirements.

*** With help of change parts.

Salient Features of Automatic Servo Base Injectable Powder Filling & Rubber Stoppering Machine

- Total cGMP model.

- +/- 2% filling accuracy depending upon vial opening and bulk density of powder.

- Toughen Glass cabinet

- PLC HMI

- Vibration free M S Frame Structure duly powered coated and covered with S.S. Sheet.

- All contact parts and assemblies coming in contact of powder and rubber stoppers are of SS 316 and easily removable for mandatory autoclaving/sterilization.

- No Vial No Fill system save wastage of costly powder

- No Stopper in Chute Machine Stop System.

- Spring loaded Teflon top seal for powder hopper reduces friction between and top seal to avoid chance of white particle shading during production.

- Adjustment of doctor blade and wiper blade can be done from outside without interruption of production saving time and wastage of powder.

- Multiple dosing of powder or changeover of vial size is achieved by changing vial separator or piston size respectively.

- Easy cleaning and maintenance of all assemblies as they are under top plate.

- Imported Gear Motor is used for better vibration-free performance of the machine or leakage of oil from gear box.

- The speed of the machine and Unscrambler and Scrambler to match with the machine is achieved through A.C. Frequency drive.

- The delrin conveyor carries the vial smoothly without sticking on it.

- The Vibrator Rubber Stopper bowl helps to run the machine at rated speed.

- Air filter of SS 316 housing with 10” length Nylon cartridge for removal of particle of 0.22 micron having 10” length

- Vacuum filter is of PVC transparent material with 10” Length Nylon Cartridge.

Automatic Servo Base Injectable Powder Filling & Rubber Stoppering Machine Optional Features

- Low air machine stop

- Low vacuum machine stop

- Door interlock

- Auto Sampling

Automatic Servo Base Injectable Powder Filling & Rubber Stoppering Machine Utility Requirement:

| Electrical supply | 1& 3 Phase + Neutral + Earthing |

|---|---|

| Electrical load | 3.5 HP. For Machine2.0 HP for Vacuum Pump |

| Pneumatic Air | Filtered, oil free, sterile low pressure 2/3 bar |

| Vacuum line | 20 Hg. |

FAQs for Injectable Powder Filling Machine (Automatic Servo Base Filler)

What types of containers can the Injectable Powder Filling Machine handle?

The Injectable Powder Filling Machine is versatile and can handle a variety of vial sizes and shapes, typically from 20 mm to 60 mm in diameter, and 58 mm to 120 mm in height. Customizable options are available to accommodate other vial sizes based on specific production requirements.

How does the Injectable Powder Filling Machine maintain sterility during the filling process?

Sterility is maintained through several mechanisms including a sterile air overpressure in the filling area, use of SS 316 material for all contact parts, and easy disassembly for autoclaving and sterilization. Additionally, the machine is enclosed in a toughened glass cabinet to prevent contamination.

Is the Injectable Powder Filling Machine suitable for small batch production?

Yes, the machine's design accommodates flexibility in production volume, making it suitable for both small batch and high volume production. The servo control system allows for easy adjustment of fill volumes and machine settings, facilitating quick changeovers and minimal downtime.

How does the Injectable Powder Filling Machine contribute to operational efficiency?

The machine enhances operational efficiency through its high automation level, including features like 'no vial, no fill', and a 'no stopper in chute, machine stop' system. These features help in reducing powder waste, minimizing downtime, and ensuring consistent production output without manual intervention.

Feel free to inquiry about Superior Quality Pharma Packaging Machinery

Inquiry NOWWe provide 24 x 7 Customer

Service & Support

Copyright © 2025, Parth Engineering & Consultant ( India ).

Web Design by Opal Infotech